Greetings !

Very often during conversations , I have seen a strange reaction on face of people when someone say that I am consulting in Maximo and the response which most of the time you'll get from those tech-heads is - "Maximo , What is Maximo...?" so here we are trying to explain and revisit my understanding over this product Maximo.

+IBM MAXIMO is a leading enterprise level asset management product used in various industries like - Manufacturing , Automotive , Oil & Gas , Transportation , Health Care , Retail which gives you immense ability to track down the cost of an asset in plant right starting from installation to its decommissioning.

It is a pioneer Asset Life Cycle and Maintenance Management Solution and part of family of software known as "CMMS"- Computerized maintenance management system.

In simple term , everything is Maximo revolves around the term - Total Cost of an Asset. In today's competitive world and atmosphere of slowing down economies , there is always pressure on industries to reduce the cost and increase the production.

One simple way to increase the production is ensuring high availability of the assets and equipment which are being used for the production line , and one of the easiest way to ensure the availability of these assets will be decreasing the downtime on them and what is the best way to ensure availability of these assets , proper and timely "maintenance" and "overhauling" to make avoid as many downtime we can and "quick" corrective maintenance and "break fix" in case of any downtime.

Consider a situation when you are planning to repair/or get it repaired by an electrician a faulty switch in switchboard in your living room. What will be first step to proceed with that ? the first thing which will come into your mind will be what you need in order to get this repair completed. You will think whether you need a special person to fix this issue with special knowledge , or you need new switch , new screw etc and most importantly what will be the cost ?

You can relate same situation with maintenance of assets used in production or non-production line where you need to track the cost and make sure that you have all needed tools , inventory and labor to perform these maintenance tasks. So Maximo gives you ability to manage and track all these entities at one place to ensure that assets in plants are getting timely maintenance and all necessary tools and equipments are available in the Inventory. If there is any shortage of such tools ,items or materials, Maximo also gives you ability to purchase them from different vendors.

So to summarize, IBM Maximo is a tool which gives you ability to track down the cost of each asset's maintenance in plant while ensuring their proper and timely maintenance to decrease downtime and increase availability of the system .

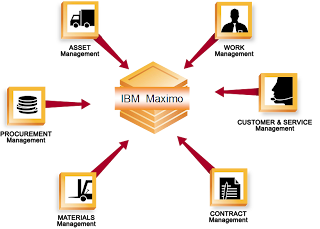

All of the functionality of Maximo can be divided into following high level modules-

We'll see more different Functional and Technical artifacts of Maximo in coming posts.....

Very often during conversations , I have seen a strange reaction on face of people when someone say that I am consulting in Maximo and the response which most of the time you'll get from those tech-heads is - "Maximo , What is Maximo...?" so here we are trying to explain and revisit my understanding over this product Maximo.

+IBM MAXIMO is a leading enterprise level asset management product used in various industries like - Manufacturing , Automotive , Oil & Gas , Transportation , Health Care , Retail which gives you immense ability to track down the cost of an asset in plant right starting from installation to its decommissioning.

It is a pioneer Asset Life Cycle and Maintenance Management Solution and part of family of software known as "CMMS"- Computerized maintenance management system.

In simple term , everything is Maximo revolves around the term - Total Cost of an Asset. In today's competitive world and atmosphere of slowing down economies , there is always pressure on industries to reduce the cost and increase the production.

One simple way to increase the production is ensuring high availability of the assets and equipment which are being used for the production line , and one of the easiest way to ensure the availability of these assets will be decreasing the downtime on them and what is the best way to ensure availability of these assets , proper and timely "maintenance" and "overhauling" to make avoid as many downtime we can and "quick" corrective maintenance and "break fix" in case of any downtime.

Consider a situation when you are planning to repair/or get it repaired by an electrician a faulty switch in switchboard in your living room. What will be first step to proceed with that ? the first thing which will come into your mind will be what you need in order to get this repair completed. You will think whether you need a special person to fix this issue with special knowledge , or you need new switch , new screw etc and most importantly what will be the cost ?

You can relate same situation with maintenance of assets used in production or non-production line where you need to track the cost and make sure that you have all needed tools , inventory and labor to perform these maintenance tasks. So Maximo gives you ability to manage and track all these entities at one place to ensure that assets in plants are getting timely maintenance and all necessary tools and equipments are available in the Inventory. If there is any shortage of such tools ,items or materials, Maximo also gives you ability to purchase them from different vendors.

So to summarize, IBM Maximo is a tool which gives you ability to track down the cost of each asset's maintenance in plant while ensuring their proper and timely maintenance to decrease downtime and increase availability of the system .

All of the functionality of Maximo can be divided into following high level modules-

- Asset and Maintenance Management

- Work Management

- Purchasing

- Inventory Management

- Resource Management

- Process Management

We'll see more different Functional and Technical artifacts of Maximo in coming posts.....

Super stuff ! Good first post !

ReplyDeleteThanks Vithun

DeleteThis comment has been removed by the author.

ReplyDeleteExcellent Prashant... Keep it coming

ReplyDeleteSuper and awesome .please post some more info related to Maximo

ReplyDeleteThanks for this informative blog on IT asset management

ReplyDeleteThanks for sharing this useful knowledge custom erp software

ReplyDeleteReally insightful! Thanks for breaking this down.

ReplyDeleteAdobe Photoshop Download

SuperAntiSpyWare Pro

PC Helpsoft Driver"